Bigbunny2007

Well-known member

- Joined

- Feb 27, 2013

- Messages

- 589

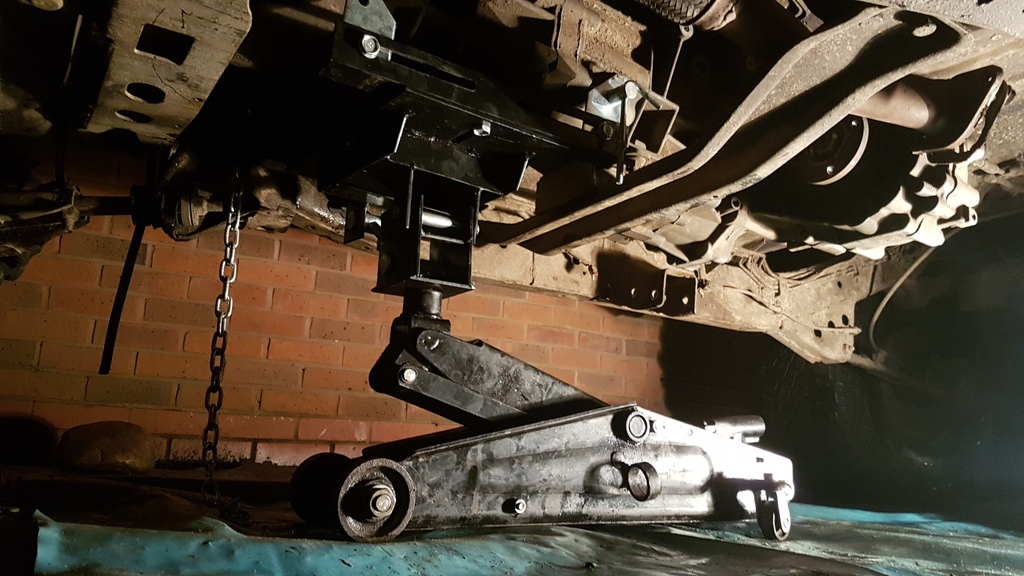

The tools look upto the job in my opinion and you are tackling the job in the correct way :thumb2

Working on your back changing a terrano clutch is a big job and one many people would not tackle so take great credit from it mate.

Your sharing your personal experience too and it will help others in the future which other forum users will appreciate. Every day is a school day and nobody knows it all

Working on your back changing a terrano clutch is a big job and one many people would not tackle so take great credit from it mate.

Your sharing your personal experience too and it will help others in the future which other forum users will appreciate. Every day is a school day and nobody knows it all