Progress

Had another crack last night at the truck when I FINALLY got home from work :doh Made some good progress again :bow

I managed to straighten out the "Claw" that I bent in the vice and it's now usable again

Had to remove the passengers side torsion bar in the same manner as the drivers side but this time it was a doddle, this time though I struggled to remove the "claw" at the adjuster end but this kind of worked in my favour as in my efforts to free it I noticed that all my banging around was actually freeing the cross member from it's mountings so the bar acted as a giant lever :thumb2 Didn't take much persuasion from the lump hammer before it finally dropped out with a little wiggling of the torsion bar.

I then moved onto the slave cylinder, easy enough to remove, 12mm bolt to remove the hose and then x2 14mm bolts to pull it away from the box.

Moving to the inside of the vehicle, I started to remove the plastic trim and leather gaiters to get at the sticks themselves, there is a thicker lower rubber gaiter that is secured with about 12 10mm screws, you know the ones...... go near them with a posi screwdriver and they turn shrapnel :lol

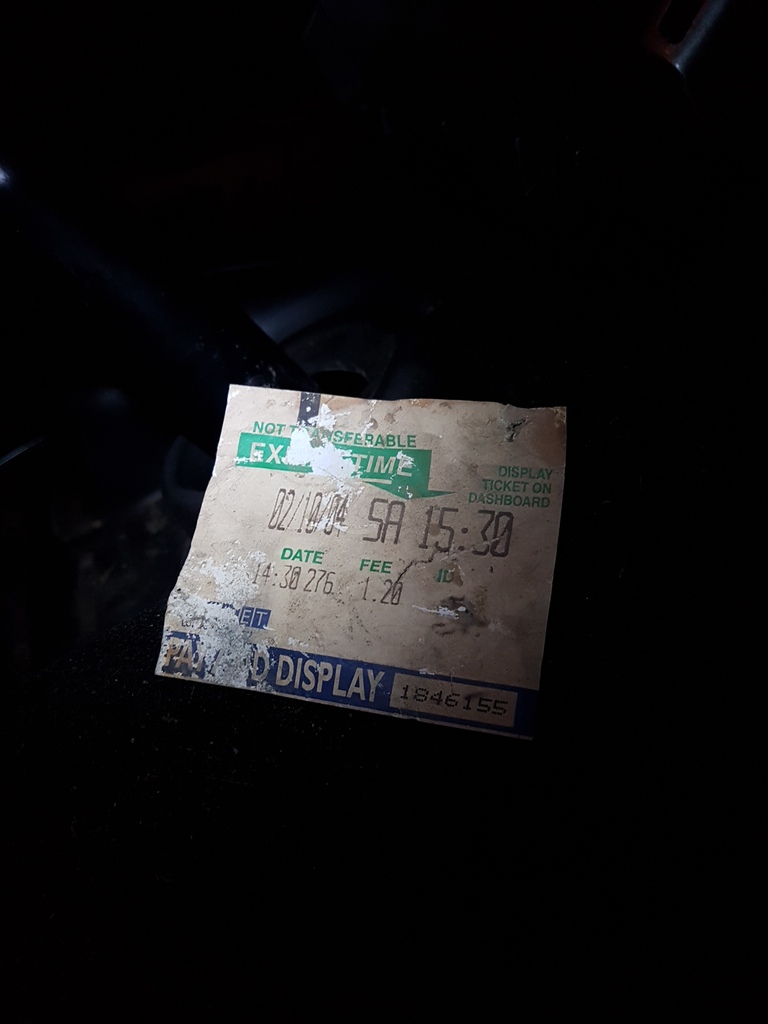

Upon removing this I felt a piece of paper as I was pulling it backwards, after a quick fish around in there I managed to retrieve a parking ticket that has gone a nice brown colour over the years from the heat of the box, looking at the date, the car was only 5 months old when that ticket was purchased. Was a pretty cool find, I like nostalgia like that and distracted me for a while with happy thoughts :lol

That's as far as I got with removing the gearsticks purely based on the fact that I broke my circlip pliers last time I used them and forgot to replace :doh They are on my list of things I need to fetch from Halfords at lunch today.

The workbench is looking a bit full now

But I'm almost ready to get the bolts out the gearbox which are as doddle to get at given I've got a 2" body lift :bow I certainly wont have to use as many extension bars as Alan did and can get to them from underneath the car rather than having to do it from inside.

Shut up shop for the night at that point and got in my jimmy jams and hit the sofa with the misses for a few hours and watched some TV, then got a ring of the doorbell at 10:40pm, the next door neighbour had just returned home and saw the lights on, she had taken a delivery for me during the day and I'd not spotted the calling card that was still folded up in the letterbox.

My gearbox cradle

Rated to 500KG and looks like it will go onto my Halfords trolley jack with not too much of a problem, going to get it built tonight

:freak3: