|

|

|||||||

| The Clubs Virtual Pub For general chat, so come on in and pull up a chair. |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: Oct 2014

Location: South west

Vehicle: Terrano

Posts: 522

|

Had the front hub from a Transit brought to me today with a broken stud so thought I would take some pics to show how I removed it with a welder.

Allen key was just to show that it had broken approx. 5mm or so below surface.  First build up with weld until it is flush with surface then place a nut on top and fill with weld. all the heat is directed in to the stud.  Allow to cool & remove with a spanner.

|

|

|

|

|

|

#2 |

|

Off road maniac

Join Date: Dec 2009

Location: Bexhill on Sea

Vehicle: Y60 Patrol Me, 3 ltr Mrs

Posts: 17,431

|

Very interesting, how did you stop the weld going onto the hub? Rick

__________________

Ex banger racer now off road maniac  Lokka on the front with manual hubs Diff lock on rear 3 inch SS straight through exhaust Manly winch bumper with 13000 lb winch 10 spike ground anchor, with multiple straps and blocks Super strong body cills capped with scaffold pole 20% stronger springs all round aggressive off road tyres on wheels so just swap. Aim to get stuck and be completely self sufficient in extraction, love getting muddy, 2ft deep is good but rare. |

|

|

|

|

|

#3 |

|

Senior Member

Join Date: Oct 2014

Location: South west

Vehicle: Terrano

Posts: 522

|

I point the torch directly at the stud welder is turned up quite high but when building up only use short burst it even works with alloy, first time I did it was with a broken stud in a alloy thermostat housing on a Skoda.

|

|

|

|

|

|

#4 |

|

Off road maniac

Join Date: Dec 2009

Location: Bexhill on Sea

Vehicle: Y60 Patrol Me, 3 ltr Mrs

Posts: 17,431

|

The local heat to the stud has clearly helped ease it's grip, must give this method a try sometime, never too old to learn, Rick

__________________

Ex banger racer now off road maniac  Lokka on the front with manual hubs Diff lock on rear 3 inch SS straight through exhaust Manly winch bumper with 13000 lb winch 10 spike ground anchor, with multiple straps and blocks Super strong body cills capped with scaffold pole 20% stronger springs all round aggressive off road tyres on wheels so just swap. Aim to get stuck and be completely self sufficient in extraction, love getting muddy, 2ft deep is good but rare. |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Oct 2014

Location: South west

Vehicle: Terrano

Posts: 522

|

Yeah trick is to let it cool otherwise you just twist the nut back off but as you say the heat is concentrated through the stud and really helps when it contracts again.

|

|

|

|

|

|

#6 |

|

Senior Member

Join Date: Oct 2014

Location: South west

Vehicle: Terrano

Posts: 522

|

I bought my first mig welder around 30 years ago & at the time my father was not a fan he thought arc welding was far better until he saw some one remove broken studs like this I remember him coming back to tell me about it it was the first time he had anything positive to say about mig welders. Now I think arc welding still has it's place but is hardly used as much.

|

|

|

|

|

|

#7 | |

|

Senior Member

Join Date: Jun 2012

Location: Sevenoaks, Kent

Vehicle: Terrano 2.7TDi SE Touring

Posts: 5,221

|

Quote:

Why doesn't the weld stick to the outer part? |

|

|

|

|

|

|

#8 |

|

Off road maniac

Join Date: Dec 2009

Location: Bexhill on Sea

Vehicle: Y60 Patrol Me, 3 ltr Mrs

Posts: 17,431

|

Agreed, I have done miles of stick welding and first MIG I got put me off for many years, then I got a mate to come help me with some tricky welding on my narrow boat, it was in the bow water tank and once inside you could hardly move, stick was a complete no no, he jumped in with his much better quality MIG and I was amazed, so I had a go and wow it was so easy, went out and bought me a reasonable MIG and never looked back, that was about 15 years ago, only use stick now for really heavy stuff and that is rare, got an oil cooled one that can weld at high amps all day but not been used for years, Rick

__________________

Ex banger racer now off road maniac  Lokka on the front with manual hubs Diff lock on rear 3 inch SS straight through exhaust Manly winch bumper with 13000 lb winch 10 spike ground anchor, with multiple straps and blocks Super strong body cills capped with scaffold pole 20% stronger springs all round aggressive off road tyres on wheels so just swap. Aim to get stuck and be completely self sufficient in extraction, love getting muddy, 2ft deep is good but rare. |

|

|

|

|

|

#9 |

|

Senior Member

Join Date: Oct 2014

Location: South west

Vehicle: Terrano

Posts: 522

|

Yes it can be done with a stick welder but it is more difficult. The outer part in this case was cast also if you are careful to direct the torch at the stud only then the weld pool just fills & does not penetrate to the side.

|

|

|

|

|

|

#10 |

|

Senior Member

Join Date: Aug 2008

Location: Derby

Vehicle: Freelander & Jeep GC 3.0

Posts: 4,416

|

That looks brilliant it looked impossible when I saw how far down the broken bit was !

|

|

|

|

|

|

#11 |

|

Senior Member

Join Date: Oct 2014

Location: South west

Vehicle: Terrano

Posts: 522

|

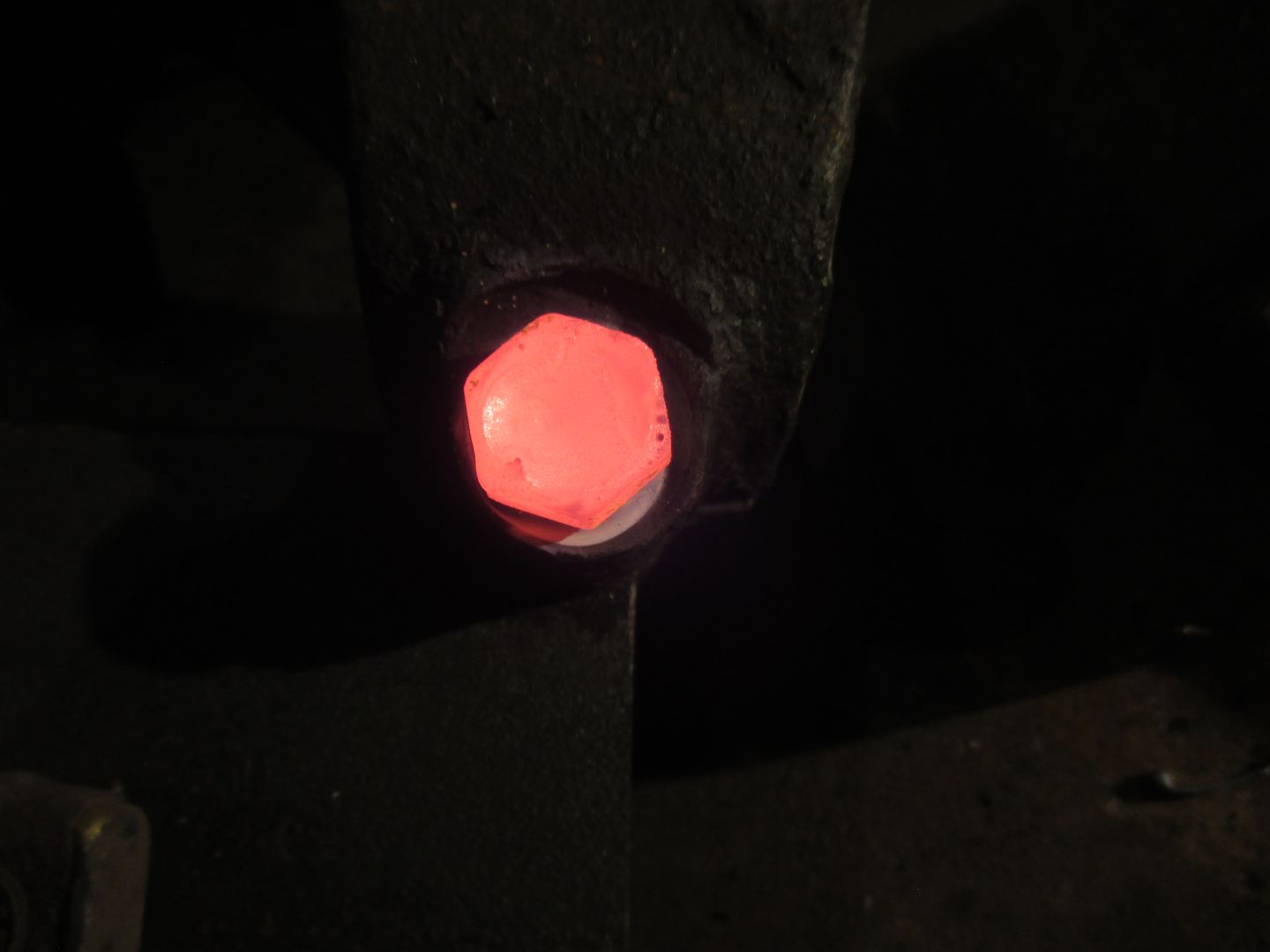

Got asked to remove this broken M4 screw from a nut today so thought I would reopen this thread. I used a washer instead of welding a nut on because of its small diameter.

|

|

|

|

|

|

#12 |

|

Senior Member

Join Date: Oct 2014

Location: South west

Vehicle: Terrano

Posts: 522

|

I decided that it was a bit small to try to weld with the stick welder so opted to use the mig. Clive asked in a previous post if it could be done with a stick welder & this is how I would normally do it with a stick welder as the washer is easier to weld through than a nut as the nut tends to trap flux.

|

|

|

|

|

|

#13 |

|

Senior Member

Join Date: Oct 2014

Location: South west

Vehicle: Terrano

Posts: 522

|

Same basic principle, weld allow it to cool then undo.

|

|

|

|

|

|

#14 |

|

Senior Member

Join Date: Apr 2016

Location: Nr J28 M1

Vehicle: 03 Terrano 2.7 TDi

Posts: 995

|

I'm impressed. Good method

As Rick said a few years back "never too old to learn"

|

|

|

|

|

|

#15 |

|

Senior Member

Join Date: Jun 2012

Location: Sevenoaks, Kent

Vehicle: Terrano 2.7TDi SE Touring

Posts: 5,221

|

I am going to have to practice this on the bench, I tried it a while back, but even allowing the nut to cool, it still just sheared off again. To be fair, it was in a horrible place on the chassis.

|

|

|

|

|

|

|